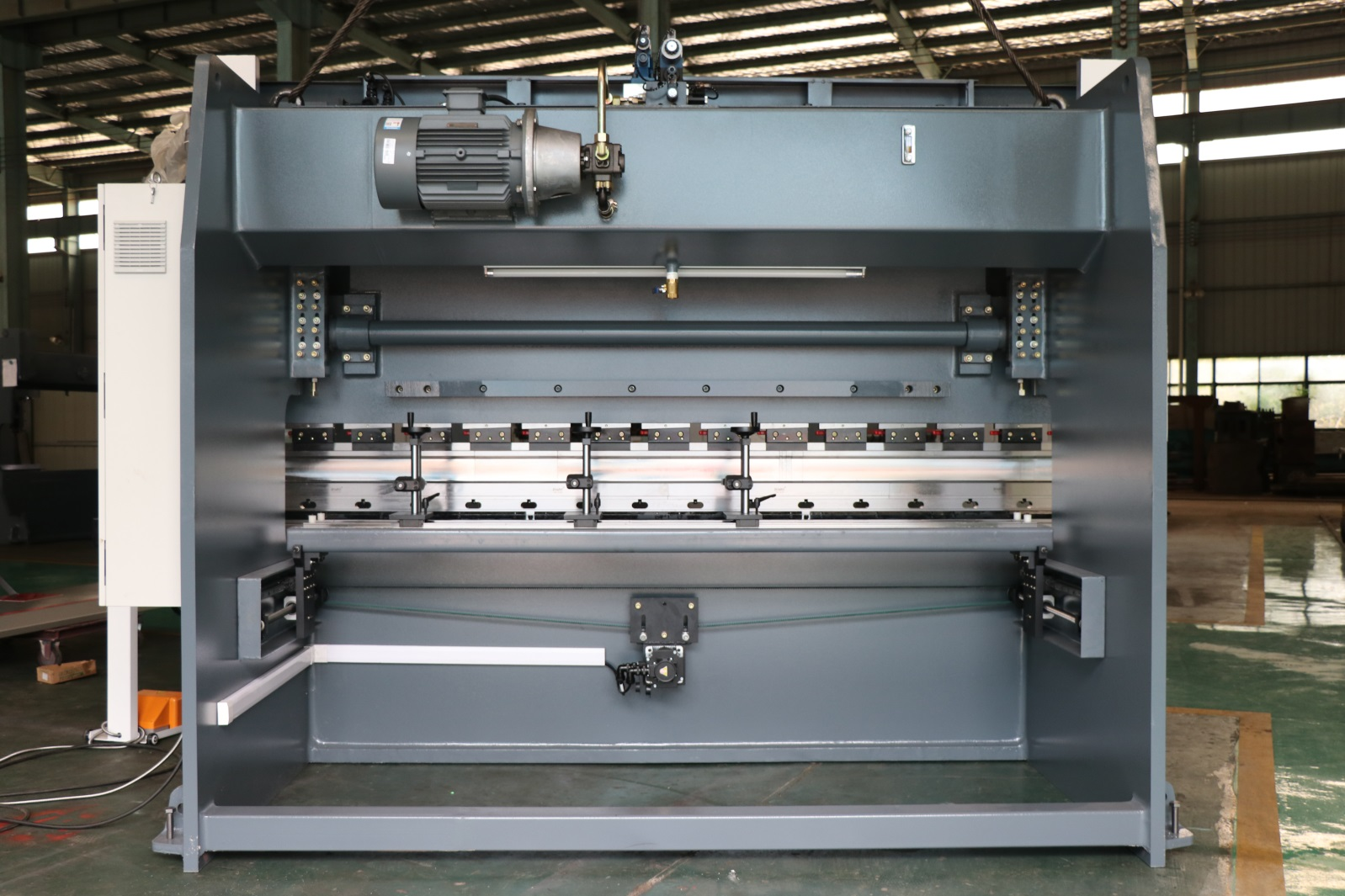

Torsion bar Synchronous CNC Press Brake

Bending Force: 40Ton-5000Ton

Bending Length:2500mm-6000mm

Controller Brand: DELEM, CYBELEC, ESA

Control Axes: 4+1/6+1/8+1axes

库存: 0

Inquire

Add to Basket

Overall welded and processed structure.

Mechanical stopper and steel torsion bar to maintain synchronization and high precision.

Movement of backgauge and ram stroke is servo controlled by Controller.

The function of angle programming of Controller will bring high bending efficiency.

X axes and y axes are controlled by servo motor, with strong synchronous belt, with high control accuracy, fastpositioning and low noise, also with electric R axes.

With imported hydraulic system, stable and high precision when persistent working.

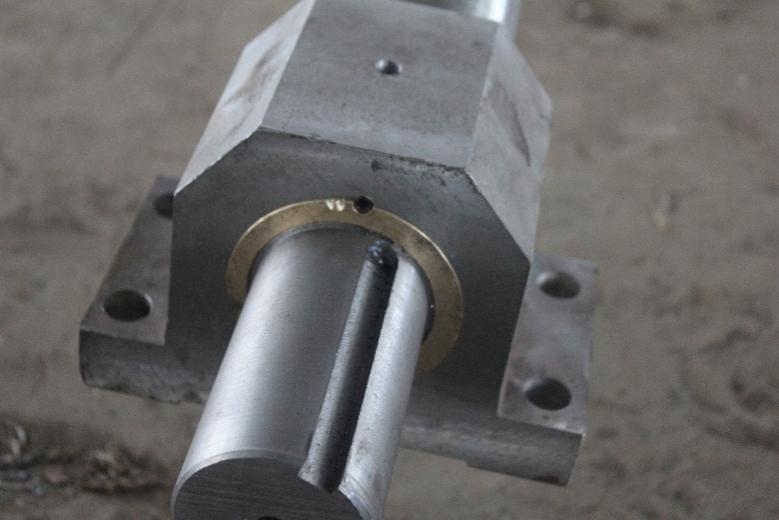

lmported ball bearing lead screw and linear quide rail are used for rear stopper, to ensure the positioning precisionof rear stopper, for processing precision of machine to be higher.

Performance Parameters

| NO. | Item | MOdel:4025 | MOdel:6325 | MOdel:8025 | MOdel:8032 | MOdel:10025 | MOdel:10032 | MOdel:10040 | MOdel:12525 | MOdel:12523 | MOdel:12540 | MOdel:16032 | MOdel:16040 | MOdel:16050 | MOdel:16060 | MOdel:20032 | MOdel:20040 | MOdel:20050 | MOdel:20060 | MOdel:25032 | MOdel:25040 | MOdel:25050 | Unit |

| 1 | Nominal pressure | 400 | 630 | 800 | 800 | 1000 | 1000 | 1000 | 1250 | 1250 | 1250 | 1600 | 1600 | 1600 | 1600 | 2000 | 2000 | 2000 | 2000 | 2500 | 2500 | 2500 | KN |

| 2 | Max. Bending | 2500 | 2500 | 2500 | 3200 | 2500 | 3200 | 4000 | 2500 | 3200 | 4000 | 3200 | 4000 | 5000 | 6000 | 3200 | 4000 | 5000 | 6000 | 3200 | 4000 | 4000 | mm |

| 3 | Max. Slider stroke | 120 | 120 | 120 | 120 | 150 | 150 | 150 | 150 | 150 | 150 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 250 | 250 | 250 | mm |

| 4 | Max. Shut height | 340 | 350 | 380 | 380 | 410 | 410 | 410 | 410 | 410 | 410 | 450 | 450 | 450 | 450 | 460 | 460 | 460 | 460 | 530 | 530 | 530 | mm |

| 5 | Between columns | 2100 | 2100 | 2100 | 2600 | 2100 | 2600 | 3100 | 2100 | 2600 | 3100 | 2600 | 3100 | 3900 | 4800 | 2600 | 3100 | 4000 | 5000 | 2600 | 3100 | 3900 | mm |

| 6 | Throat depth | 250 | 250 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 350 | 350 | 350 | 350 | 400 | 400 | 400 | mm |

| 7 | Main motor power | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 11 | 11 | 11 | 15 | 15 | 15 | 15 | 18.5 | 18.5 | 18.5 | KW |

| 8 | Down Speed | 120 | 120 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 90 | 90 | 90 | mm/min |

| 9 | Pressing Speed | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | mm/min |

| 10 | Return Speed | 100 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | mm/min |

| 12 | X axes Stroke | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | mm |

| 13 | X axes Speed | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | mm/s |

| Overall dimension---L/WH | 3000 | 3000 | 3000 | 3700 | 3000 | 3700 | 4500 | 3000 | 3700 | 4500 | 3700 | 4500 | 5500 | 6500 | 3700 | 4500 | 5500 | 6500 | 3700 | 4500 | 6500 | mm | |

| 14 | 1400 | 1500 | 1600 | 1600 | 1750 | 1750 | 1750 | 1750 | 1800 | 1800 | 1870 | 1920 | 1920 | 1920 | 2000 | 2000 | 2000 | 2000 | 2150 | 2150 | 2200 | mm | |

| 2000 | 2200 | 3200 | 2300 | 2400 | 2400 | 2450 | 2450 | 2450 | 2450 | 2450 | 2800 | 2800 | 3100 | 3300 | 2850 | 2850 | 3000 | 3300 | 3000 | 3500 | mm |

Detail Pictures

The Torsion bar Synchronous CNC Press Brake warranty period is 2 years, will run since bill of lading date, if the accessories appear damaged during the warranty period, except for damage caused by improper human handling, we can replace them for the buyer for free.

Front

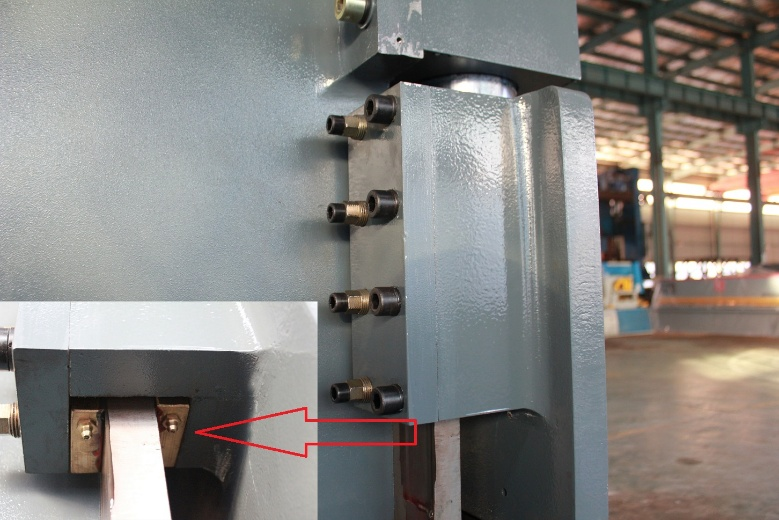

Back

Siemens main motor German brand.

The guideway use the brass, wear-resisting, Double sliding front support arm installed

long service life.

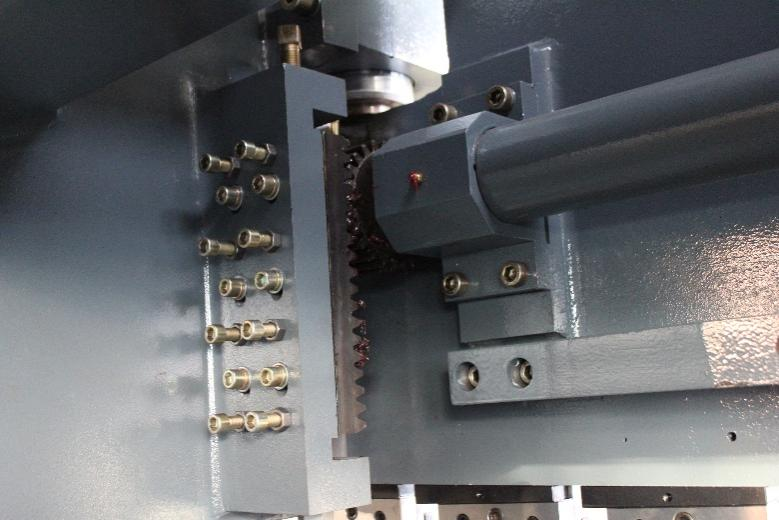

The torsion bar is synchronized with the gear rack. ram down fast, easy to adjust the two sides of the synchronization. The connector use wear - resistant brass.

X-axes servo motors.

Y-axes servo motors.

Main Configuration

| Name | Producer |

| CNC controller | TP10S YC technology China brand |

| Main motor | Siemens Germany brand |

| Electrical components | Schneider France brand |

| Gear pump | First USA brand |

| Seal ring | NOK Japan brand |

| Hydraulic system | Boschrexroth Germany brand |

| Ball screw, Linear guide | Hawk king Taiwan brand |

| Tubing connector | EMB Germany Brand |

| Servo Motor and drive | TP10S YC technology China brand |